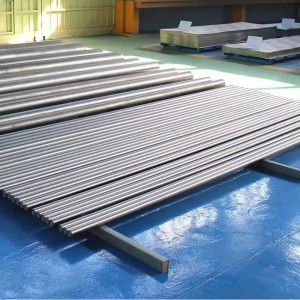

HastelloyB-3 / UNS N10675 Tube, Efere, Ngwa akwa, Forgings, Mkpanaka

Ngwaahịa dị

Ọkụ na-enweghị nkebi, Efere, Mkpanaka, Forgings, Fasteners, Strip, Waya, Pipe Fittings

Ụkpụrụ mmepụta

| Ngwaahịa | ASTM |

| Ogwe | B 335 |

| Efere, mpempe akwụkwọ na warara | B 333 |

| Ọkpụkpọ na akwa akwa na-enweghị ntụpọ | B 366 |

| Ọkpọkpọ aha welded | B 619 |

| Ọkụ welded | B 626 |

| Ngwakọta ọkpọkọ welded | B 366 |

| Ọkpụkpọ ọkpọkọ adịgboroja ma ọ bụ akpọrepu na ngwa ọkpọkọ arụrụ arụ | B462 |

| Billets na mkpanaka maka ịgha mkpụrụ | B472 |

| Forgings | B 564 |

Ngwakọta kemịkalụ

| % | Ni | Cr | Mo | Fe | Ti | Co | C | Mn | Si | P | S | V | Ti | Cu | Nb |

| min | Nhazi | 1.0 | 27.0 | 1.0 | |||||||||||

| max | 3.0 | 32.0 | 3.0 | 0.2 | 3.0 | 0.01 | 3.0 | 0.1 | 0,030 | 0.010 | 0.2 | 0.2 | 0.2 | 0.2 |

Njirimara anụ ahụ

| njupụta | 9.22 g/cm3 |

| Na-agbaze | 1330-1380 ℃ |

Hastelloy B-3 alloy bụ onye ọhụrụ sitere na ezinụlọ nke nickel-molybdenum alloys, nke nwere ezigbo mgbochi corrosion na hydrochloric acid na okpomọkụ na itinye uche ọ bụla.N'otu oge ahụ, ọ nwekwara ezigbo mgbochi corrosion na sulfuric acid, acetic acid, formic acid, phosphoric acid na ndị ọzọ na-abụghị oxidizing media.Ọzọkwa, n'ihi ngbanwe nke ihe mejupụtara kemịkalụ ya, a na-eme ka nkwụsi ike ọkụ ya dịkwuo mma ma e jiri ya tụnyere ihe mbụ Hastelloy B-2 alloy.Hastelloy B-3 alloy nwere nnukwu iguzogide pitting corrosion, nrụgide corrosion cracking, mma corrosion na corrosion na okpomọkụ metụtara mpaghara ịgbado ọkụ.

Hastelloy B-3 alloy bụ ihe ọzọ dị elu na nickel alloy na-esote B-2 alloy.Ọ nwere kemịkalụ kemịkalụ a haziri nke ọma iji nweta ọkwa dị elu nke nkwụsi ike ọkụ karịa ihe ndị ọzọ Hastelloy alloys dị ka B-2 ma nwee ezigbo nguzogide pitting, crevice corrosion, corrosion stress, corrosion mma na thermal mmetụta ikike imebi.N'ihi nkwụsi ike nke okpomọkụ nke B-3 alloy, nsogbu ndị a na-enwe na mmepụta akụkụ dị ka B-2 alloy na-ebelata n'ihi mbelata mmiri ozuzo nke etiti etiti na-emerụ ahụ na usoro B-3 alloy.Nke a na-enye ductility dị elu karịa alloys B-2 n'okpuru ọnọdụ ịgba ígwè dị ka nkedo na ịgbado ọkụ.

Nickel-molybdenum alloy a nwere ezigbo nguzogide na mkpokọta hydrochloric acid n'ọnọdụ ihu igwe dị elu.Ọ na-eguzogidekwa sulfuric, acetic, formic na phosphoric acid na mgbasa ozi ndị ọzọ na-adịghị oxidizing.B-3 nwekwara ezigbo iguzogide pitting na nrụgide corrosion cracking.

Njirimara ihe nke B-3 Alloy

Nguzogide dị mma na hydrochloric acid na mkpokọta na ọnọdụ okpomọkụ niile, iguzogide sulfuric, acetic, formic na phosphoric acid na mgbasa ozi ndị ọzọ na-abụghị oxidizing Nguzogide dị oke egwu na mgbawa nke pitting na nrụgide corrosion.

Ngwa a na-ahụkarị nke Hastelloy B3

A na-ejikarị usoro alloys Hastelloy B na gburugburu ebe siri ike na-emebi emebi, a na-ejikwa ya na kemịkalụ, petrochemical, ike na mpaghara nchịkwa mmetọ, karịsịa na ụlọ ọrụ dị ka sulfuric acid, hydrochloric acid, phosphoric acid, na acetic acid, dị ka distillation. na itinye uche nke hydrochloric acid;obere nrụgide Oxylated acetic acid (HAC);halogenated butyl roba (HIIR);polyurethane akụrụngwa na ethylbenzene alkylation mmepụta na ndị ọzọ usoro akụrụngwa.

N'ihi ọnụ ahịa dị elu, ngwa Hastelloy B usoro alloys na-etinyekarị uche, ọkachasị na mmepụta nke acetic acid (oxo synthesis) na ụfọdụ sistemu mgbake sulfuric acid, dị ka evaporators na itughari tankị nchekwa sulfuric acid na acetic acid engineering.