Ọkachamara onye nrụpụta Alloy na-eguzogide corrosion 926/ Incoloy926/ UNSN08926/ 1.4529

Ngwaahịa dị

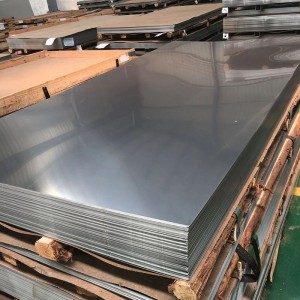

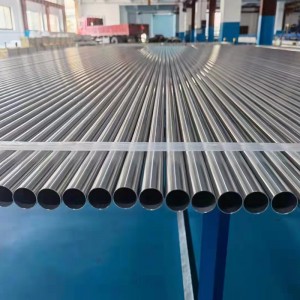

Ọkpụkpọ enweghị nkebi, Efere, Mkpanaka, Forgings, Fasteners, Pipe Fittings

Ụkpụrụ mmepụta

| Ngwaahịa | ASTM |

| Ogwe, Rod na waya | B 649 |

| Efere, Mpempe akwụkwọ na warara | A 240, A 480, B 625, B 906 |

| Ọkụ na tubes enweghị nkebi | B 677, B 829 |

| Ọkụ welded | B 673, B 775 |

| Weld tube | B 674, B 751 |

| Ngwakọta ọkpọkọ welded | B 366 |

| Billets na mpempe akwụkwọ maka ịgha mkpụrụ | B472 |

Ngwakọta kemịkalụ

| % | Fe | Ni | Cr | Mo | C | Mn | Si | P | S | Cu | N |

| Min | itule | 24.0 | 19.0 | 6.0 |

|

|

|

|

| 0.5 | 0.15 |

| Oke | 26.0 | 21.0 | 7.0 | 0.020 | 2.0 | 0,50 | 0,030 | 0.010 | 1.5 | 0.25 |

Njirimara anụ ahụ

| Njupụta | 8.1g / cm3 |

| Na-agbaze | 1320-1390 ℃ |

Incoloy 926/1.4529 Njirimara ihe

Incoloy926/1.4529 nwere nnukwu nguzogide na pitting na crevice corrosion na halide media na gburugburu acidic nwere sọlfọ na hydrogen, nwere ike iguzogide corrosion nrụgide chloride ion nke ọma, yana nwekwara ezigbo nguzogide corrosion na oxidizing na ibelata mgbasa ozi.nkwụsi ike na nkwụsi ike.Ezi, n'ibu Njirimara bụ ubé mma karịa 904L, nke a pụrụ iji rụpụta nsogbu arịa nke -196 ~ 400 ℃.

INCOLOY Alloy 926 (UNS N08926 / W. Nr. 1.4529 / INCOLOY Alloy 25-6MO) bụ nnukwu austenitic igwe anaghị agba nchara nwere 6% molybdenum ma gbakwụnye ya site na mgbakwunye nitrogen.Ọdịnaya nickel na chromium nke alloy a na-eme ka ọ bụrụ ihe na-eguzogide ọnọdụ dị iche iche na-emebi emebi.Alloy na-eguzogide ọgwụ ndị na-adịghị oxidizing dị ka sulfuric na phosphoric acid.Ọdịnaya molybdenum dị elu na nitrogen na-enye iguzogide pitting na crevice corrosion, ebe ọla kọpa na-abawanye iguzogide sulfuric acid.

INCOLOY 926 alloy bụ 6% molybdenum zuru oke austenitic alloy nwere ezigbo nguzogide corrosion n'ọtụtụ corrosive na gburugburu mmiri.Ọ na-edochi omenala austenitic igwe anaghị agba nchara (AISI 316 na 317), ebe ike ha eruola oke arụmọrụ ha.Ya mere, alloy a bụ nke ụdị nke "Super Austenitic igwe anaghị agba nchara".Ọ nwekwara ike na-anọchi anya ihe ọzọ dị ọnụ ahịa karịa nickel alloys dị elu na mpaghara ụfọdụ nhazi mmiri na kemịkal.

Otu n'ime ihe pụtara ìhè nke INCOLOY 926 alloy bụ iguzogide gburugburu ebe nwere chlorides ma ọ bụ ihe ndị ọzọ.Alloy a dabara adaba maka ijikwa gburugburu chloride dị elu dị ka mmiri brackish, mmiri oke osimiri, caustic chloride na sistem igwe igwe na-acha ọcha.Ngwa gụnyere kemịkalụ na nhazi nri, osisi pulp na akwụkwọ ịcha ọcha, akụrụngwa mmiri na nke dị n'akụkụ mmiri, ihe mgbapụta nnu, sistemu njikwa mmetọ ikuku, ọkpọkọ condensate, ọkpọkọ mmiri na mmiri ọkụ na ụlọ ọrụ ọkụ.

Mpaghara Ngwa Ngwa Incoloy 926/1.4529

1. Ọ nwere nnukwu iguzogide pitting na crevice corrosion na acidic media nwere halides na hydrogen sulfide.

2. N'ime ngwa bara uru, ọ dị irè megide mgbawa corrosion chloride.

3. Ọ nwere ezigbo nguzogide corrosion dị iche iche na gburugburu redox nkịtị.

4. Mmezi akụrụngwa n'elu Cronifer 1925 LC-Alloy 904 L.

5. Alloy ahụ emewo ka nkwụsi ike nke ọla dị mma tụnyere alloys na 18% nickel range.

Akụkụ desulfurization gas maka mmepụta phosphoric acid, ndị na-ekpo ọkụ, ndị na-ekpo ọkụ, ihe nzacha na ndị na-agwakọta, ihe na-ebuga sulfuric acid, condensers, sistemu ọkụ ọkụ, sistemu mmiri mmiri mmiri, sistemu hydraulic na ọkọnọ sistemu na ụlọ ọrụ dị n'ụsọ osimiri, sistemu pulp, condenser nnu evaporative, ụlọ ọrụ ọkụ na-emetọ usoro ọkpọkọ mmiri jụrụ oyi, ngwaọrụ desalination osmosis seawater, tankị nchekwa ụgbọ njem na-emebi emebi, akụrụngwa halogen acid catalytic organic okwu mmepụta akụrụngwa, wdg.